Setting the Standard Since 1991

With

our products of high quality standards, we are building reputation in

the market. We follow a comprehensive approach to conduct rigorous tests

and meet the exact requirements of customers.

QA Framework

We

have maintained a specialized R&D division, which enables us to

conduct comprehensive quality tests and build reputation in the market.

The strict quality tests that we conduct serve as pillars of our QA

framework.

We supply our range after passing it through the following tests:

-

Ash content test

- Colour consistency test

- Charpy impact test

- Density test

- Falling test

|

-

Heat aging evaluation test

- Heat reversion

assessment test

- Surface glass test

- Vicat softening point

analysis test

- Welding strength evaluation test

|

Global Standard Certifications

|

|

-

Shriram

- National Test House

- RoHS Compliant

- BIS

|

Manufacturing Standards

We

are trusted by customers for complying with the EN12608- 2016 and

European standards for developing our products. Each of our products is

developed by employing the environmental friendly materials and with

calcium and zinc-based formulation, due to use of such materials, our

products have unmatched level of UV resistance and weld strength. We

procure world-class raw materials from Europe to develop our products

for your homes. Furthermore, we employ cutting-edge PLC/SCADA based Auto

Weighing and Batching system with advanced gloss level.

Our

products are praised for their operational excellence, ventilation,

aesthetics and robustness due to our fine craftsmanship and use of

suitable textures, gradients and edges.

Green Initiatives

We

are committed to working towards bringing a sustainable tomorrow begins

and for us it starts with a low carbon footprint. With our eco-friendly

uPVC windows and doors profiles, we work for a greener future. When

customers purchase our uPVC, they opt for sustainability and an

intelligent, futuristic approach. We contribute to protection of natural

resources by offering products that are more energy-efficient than wood

or plastic and provide excellent thermal insulation at low cost.

Furthermore, our products are praised in the market for remaining in the

same shape and sizes in all the weather conditions.

We

take utmost pride in our environmentally responsible approach and green

practices that ensure our every step contributes to a healthier planet.

We have installed solar panels across all our production facilities.

With these facilities, we harness clean energy and reduce our

environmental footprint and power to develop eco-friendly products.

Our Advanced Infrastructure

R&D Centre

The

cutting-edge R&D Centre that we have maintgained is fully devoted

to help us have innovation and constant product development. A

knowledgeable team of professionals handles our cutting-edge research

operations. Ensuring quality is our first focus, and we adhere strictly

to EN 12608-1-2016 requirements. Our lead-free uPVC profiles guarantee a

more environmentally friendly future.

Simta Astrix Laboratory Equipments

We

have maintained modern laboratory equipment to conduct quality tests.

We have maintained a subzero unit for low temperature evaluations, a

universal testing machine for strength tests, and an impact tester for

profile strength. In order to be fully assured of the quality of uPVC

compounds and assess thermal qualities, we have maintained a Filler

Content Tester, a Density Tester, and a Hot Air Oven.

Furthermore,

we have amenities to conduct Vicat Softening Temperature Test for

assessing thermal properties, Spectrophotometer and Gloss Meter to

analyze colour and surface finish; and a Hardness Tester to measure the

rigidity.

Raw Material Sourcing

When

it comes to procuring premium raw materials for manufacturing our uPVC

windows and doors, Simta Astrix stands tall in the industry. These

materials are imported by us from reputable worldwide vendors like

DuPont, LG, and Kaneka. Our choice of PVC resin remains in an ethylene

basis and unique additives covered in silicate that ensures supreme

qualities such as thermal stability and mechanical strength.

In

addition, we regularly buy approved-grade chemicals from Fortune 500

firms across the globe. We also source foils for the exterior from

respectable German manufacturers such as Renolit. Our reputation in the

market for delivering high quality uPVC products is built on our

unwavering dedication to excellence in sourcing.

Advanced Machinery

Silos-

We believe that silos are essential to increasing the productivity of

our manufacturing process. These silos enable smooth raw material

storage because they are outfitted with intelligent automation and

monitoring systems. They are used to have accurate inventory control,

which has significantly decreased downtime and material waste.

We

have achieved excellent production in the industry thanks to our

sophisticated silos. They allow us to optimise our manufacturing

processes, which leads to improved cost-effectiveness, faster turnaround

times, and higher-quality products.

Batching

and Weighing- Precision weighing systems are incorporated into our

technology, which allows us to precisely monitor and manage a number of

important characteristics. Our products constantly fulfil the highest

quality requirements thanks to our careful control over quantities

including weight, size, and materials.

Our

sophisticated PLC/SCADA systems offer real-time control and monitoring

of our manufacturing operations. Our ability to closely comply with

industry laws and standards is because of our latest technology, which

guarantees error-free production of uPVC windows and doors.

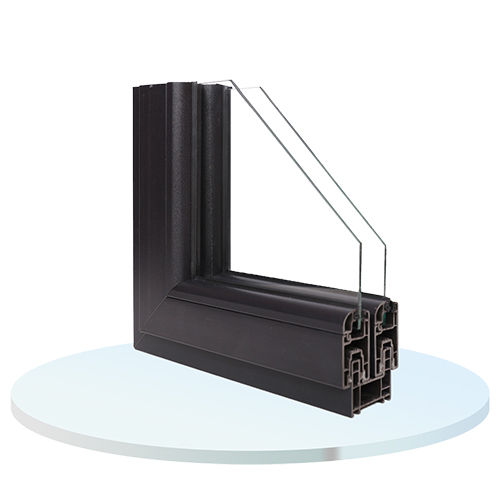

Lines of Extrusion

At

Simta Astrix, we have integrated cutting-edge extruder machinery from

Europe into our manufacturing procedures. We have over 15 cutting-edge

extrusion machines that play a critical role in our dedication to

producing high-quality goods.

We

also use European extruders to produce uPVC profiles with remarkable

accuracy and repeatability. No matter how complex the design of a window

frame or how durable a door profile needs to be, our extruder machines

help us in creating high-quality, dependable products.

Profile Lamination Facility

An

excellent illustration of our dedication to quality is our Profile

Lamination Facility. This facility is equipped with cutting edge hot

melt PUR (Polyurethane Reactive) technology that allows us to precisely

and elegantly perform the wrapping profile work for interior

applications.

We

can perfectly envelop profiles with an unwaveringly high-quality foil

thanks to this sophisticated process, which also help us to bring

unmatched finish that improves durability and appearance. Our Profile

Lamination Facility makes sure that every product including the window

casings and door frames, is made with the highest attention to detail.

Storage and Dispatch

Our

dependable logistics infrastructure help us to ensure that deliveries

go off without a hitch. Our capacity to deliver laminated profiles has

improved greatly because of the cutting-edge technology that we have

maintained. We can now ensure delivery in as little as 15 days from

taking the orders.

Even

in the highly competitive market, we are able to have remarkable

production because of our continuous dedication to quality and effective

supply chain management procedures.

We

have remarkable warehousing capabilities that enable us to hold premium

raw materials after sourcing from vendors all around the world. The

vendors we have linked with can go past production roadblocks and give

fabricators the dependability and convenience they require to work

efficiently.